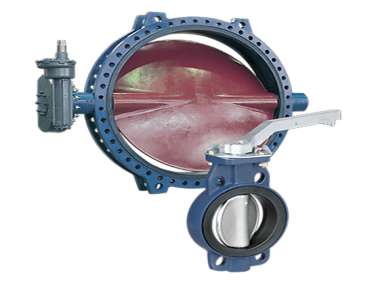

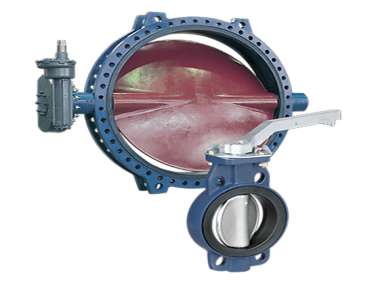

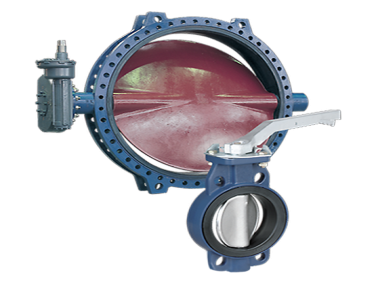

Keystone Model ParaSeal Butterfly Valves

006482-HW-KEYSTONE-082

Overview

The ParaSeal range features a proven disc, shaft and seat arrangement designed for use in high pressure and high velocity applications

| Certifications | DVWG, PED |

| End Connection | Flanged, Lugged, Wafer |

| Application | Desalination, Water distribution, Chillers, Balance of Plant, Water Treatment |

| Body Design | Short Pattern |

| Material | Epdm Rubber, Duplex, Ductile Iron, Cast Iron, Carbon Steel, Buna-N, Bronze, 316L Stainless Steel, 316 Stainless Steel, 304 Stainless Steel, Aluminum Bronze |

| Operating Temperature | Less Than 200 C |

| Pressure Class | ASME, PN |

| Process Connection Type | 125FF, 150RF, PN16, PN25, 150FF |

| Seat/Seal Type | Resilient |

| Shutoff Class | Zero Leakage |

| Valve Size | NPS 6 / DN 150, NPS 4 / DN 100, NPS 3 / DN 80, NPS 24 / DN 600, NPS 2-1/2 / DN 65, NPS 20 / DN 500, NPS 2 / DN 50, NPS 18 / DN 450, NPS 16 / DN 400, NPS 14 / DN 350, NPS 12 / DN 300 |

| Valve Size Standard | NPS, DN |

| Valve Type | Butterfly |

| Media | Air, Air, Inert Gas, Water |

| Stem | O-ring |

The valve product is available in wafer, lugged, and double-flanged configurations, designed to meet diverse application needs. It features a robust one-piece body design according to ISO 5752 series 20 (DIN 3202 K1), ensuring reliability and consistency in performance. This valve is engineered for demanding environments, suitable for both severe vacuum conditions and pressures up to 25 bar, providing a bubble-tight shutoff.

The valve’s design includes a field-replaceable seat, which fully isolates the body and shaft from the media, protecting critical components and extending the valve’s lifespan. Its bed grooved seat construction ensures tight shutoff even at the full rated pressure, making it effective for end-of-line service. Additionally, it is compatible with Bördel and slip-on flanges, offering flexibility in installation.

To enhance flange sealing, the valve incorporates a molded-in O-ring within the seat face, eliminating the need for additional flange gaskets. The lenticular-shaped disc is specifically designed to improve flow capacity, optimizing the valve’s performance. The connection between the disc and shaft is customizable with splined, squared, or key-shaped configurations, providing versatility depending on application needs.

The valve also features a dry shaft design and PTFE-lined bearings, which minimize friction and contribute to the smooth operation and extended service life. For ease of automation, it is equipped with an actuator flange that conforms to ISO 5211 standards, allowing for seamless actuator integration.